Elbow

Buttweld 90 Degree Elbow Material & Grades

Stainless Steel Buttweld 90° Pipe Elbow :

ASTM A403 WP316/316L, ASTM A403 SA / A 774 WP-S, WP-W, WP-WX 304/304L, ASTM A182

F316L, 304L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404

Duplex & Super Duplex Steel Buttweld 90° Pipe Elbow :

ASTM A 815, ASME SA 815 UNS NO S31803, S32205. UNS S32750, S32950. Werkstoff No.

1.4462

Carbon Steel Buttweld 90° Pipe Elbow :

ASTM A234, ASME SA234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65

& WPHY 70.

Low Temperature Carbon Steel Buttweld 90° Pipe Elbow : ASTM A420 WPL3, A420 WPL6

Alloy Steel Buttweld 90° Pipe Elbow :

ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

Nickel Alloy Buttweld 90° Pipe Elbow :

ASTM B336, ASME SB336, Nickel 200 (UNS No. No2200), Nickel 201 (UNS No. N02201),

Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No.

N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625

(UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No.

N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II), Cupro-Nickel

70/30, CuNi10Fe1Mn, CuNi30Mn1Fe.

Manufacturing Standards of Buttweld 90 Degree Elbow

| ASME Standard | ASME/ANSI B16.9, ASME/ANSI B16.28, MSS-SP-43 |

|---|---|

| DIN Standard | DIN28011, DIN2617, DIN2616, DIN2615, DIN2605 |

| EN Standard | EN10253-2, EN10253-1 |

| ASME B16.25 | Buttwelding Ends |

| ASME B16.9 | Factory-Made Wrought Fittings Buttwelding |

| ASME B16.28 | Wrought Steel 90 Degree SR Elbows and Wrought Steel 90 Degree LR Elbows |

| ASTM A403 – ASME SA403 | Standard Specification for Wrought Austenitic Stainless Steel Piping Fitting |

| MSS SP-43 | Wrought & Fabricated Butt-Welding Fitting for Low Pressure, Corrosion Resistant Applications |

Stainless Steel: ASTM A 312, A 213, A 213, A 249, A 269, A 358, A 240, A 276

Type: 202, 304, 304L, 304, 304H, 316, 316L, 316Ti, 321, 321H, 317, 317L, 310, 310S, 409, 410, 420, 430 etc.

Carbon Steel: ASTM A 106, A 53, API A 5L Gr A, B, C, ASTM A 333, Gr 1 to 6 (IBR & NON IBR)

Alloy Stel: ASTM A 335, GR P1, P2, P5, P9, P11, P22, P91

Nickel Alloys: Monel 400 & 500, Inconel

600 & 625, Incolloy 800, 825, Hastelloy 904, Titanium, Tungston, SIlver Nickel, Zirconium, Palladium, Vanadium etc.

Copper Alloys: Aluminium, Copper, Brass & Gunmetal

Buttweld & Forged Fittings: ASTM A 403, A182, A 234, A 105, A 420, A 350 & LF2 etc. (IBR & NON IBR)

Types : Elbow, Tee, Reducer, Return Bends, Stub-Ends, Cap, Colla, Cross, Insert, etc.

Size : 1/8"NB TO 48"NB. (seamless & welded)

Wall thickness : sch. 5s to sch.xxs.

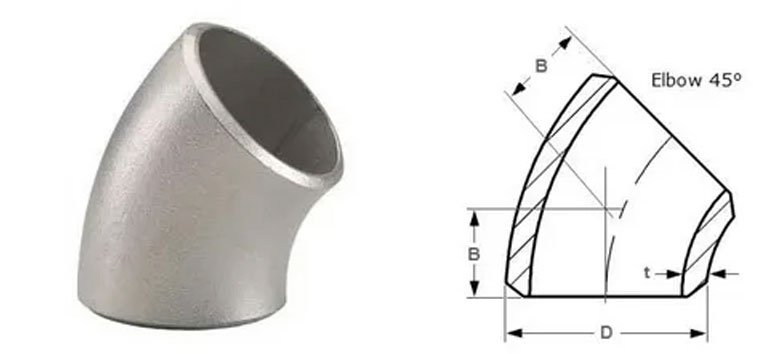

Buttweld 45° Elbow Production Range

| Outside Diameter: | Seamless Elbow ( 1/2″~24″), ERW / Welded / Fabricated Elbow (1/2″~48″) |

|---|---|

| Wall Thickness: | 3mm – 40mm / SCH3, SCH10, SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Bending Radius: | R=1D – 10D, 15D, 20D |

| Product’s Angle: | 5° – 180° Elbows, 90° and 45° Long Radius Elbows, Long Radius Returns, Short Radius Elbows and Returns |

| Value Added Services: | Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Threading, Soldering |

| Production Grades: | Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low temperature Steel, Carbon Steel, Cupro Nickel |

Manufacturing Standards

| ASME: | ANSI B16.9, ANSI B16.28, MSS-SP-43 |

|---|---|

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

| ASTM A403 – ASME SA403 | Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings |

|---|---|

| ASME B16.9 | Factory-Made Wrought Fittings Buttwelding |

| ASME B16.25 | Buttwelding Ends |

| ASME B16.28 | Wrought Steel Short Radius Elbows and Buttwelding Returns |

| MSS SP-43 | Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications |

Pipe Elbow Material Grades

| Stainless Steel Elbow | ASTM A403 WP Gr. 304L ,304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L |

|---|---|

| Carbon Steel Elbow | ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. |

| Low Temperature Carbon Steel Elbow | ASTM A420 WPL3, A420 WPL6 |

| Alloy Steel Elbow | ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 |

| Duplex Steel Elbow | ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Werkstoff No. 1.4462 |

| Nickel Alloy Elbow | ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 ) |